Your Complete Manual to Preventing Weld Undercut Like a Pro

Your Complete Manual to Preventing Weld Undercut Like a Pro

Blog Article

Grasping the Art of Welding: How to Stay Clear Of Undercut Welding Issues for Flawless Manufacture Results

Effectiveness and precision are critical on the planet of welding, where even the least blemish can compromise the architectural stability of a made piece. One usual obstacle that welders face is undercutting, a flaw that can lead and deteriorate a weld joint to expensive rework. By understanding the source of undercut welding and executing efficient techniques to stop it, welders can elevate their craft to brand-new degrees of excellence (Preventing weld undercut). In the search of perfect construction results, mastering the art of welding to avoid undercut problems is not just a skill yet a requirement for those making every effort for excellence in their job.

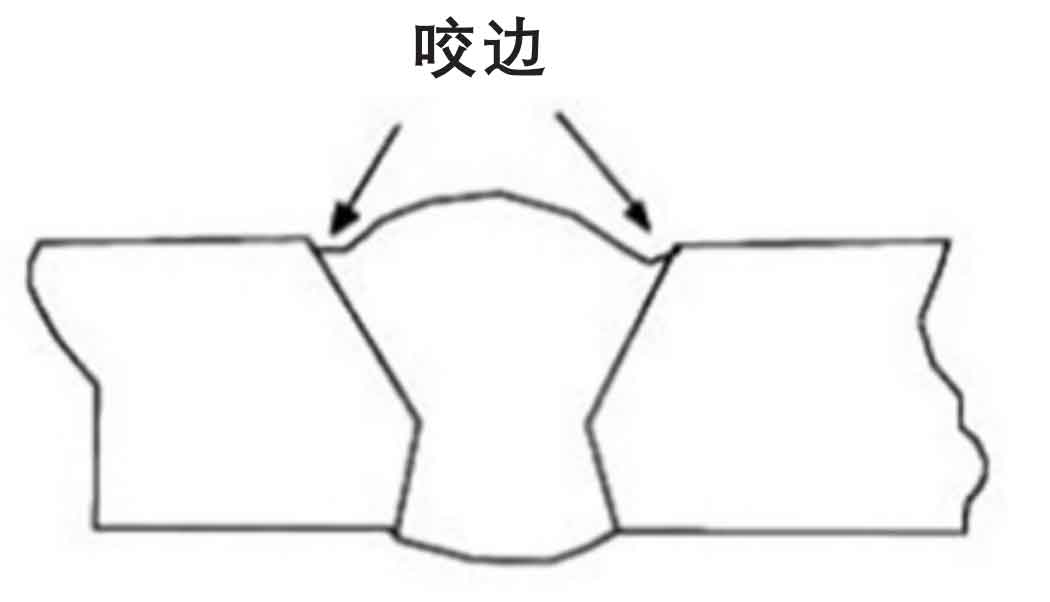

Recognizing Undercut Welding

To stop undercut welding, welders ought to guarantee correct welding criteria, such as changing the current, voltage, travel rate, and preserving the correct electrode angle. By comprehending the reasons of undercut welding and applying preventative procedures, welders can achieve top quality, structurally sound welds.

Sources Of Undercut in Welding

Understanding the factors that add to undercut in welding is crucial for welders to create top notch, structurally audio welds. Poor welding inaccurate or current welding rate can also add to damage. Comprehending these reasons and carrying out correct welding strategies can assist protect against undercutting issues, making certain solid and long lasting welds.

Techniques to stop Undercutting

To reduce the danger of undercutting in welding, welders can employ strategic welding techniques intended at boosting the top quality and honesty of the weld joints. In addition, utilizing the right welding method for the certain joint setup, such as weave or stringer beads, can contribute to lowering damaging.

Employing back-step welding strategies and regulating the weld bead account can also aid distribute warm uniformly and minimize the danger of undercut. Normal evaluation of the weld joint throughout and after welding, as well as implementing quality guarantee actions, can aid in resolving and discovering damaging issues without delay.

Significance of Appropriate Welding Criteria

Selecting and preserving appropriate welding specifications is essential for accomplishing effective welds with minimal issues. Welding parameters refer to variables such as voltage, present, take a trip rate, electrode angle, and securing gas flow rate that directly affect the welding procedure. These criteria have to be thoroughly changed based upon the sort of product being bonded, its density, and the welding strategy employed.

Proper welding criteria guarantee the appropriate quantity of warm is used to thaw the base steels and filler material consistently. If the parameters are set as well high, it can result in extreme warm input, causing spatter, distortion, or burn-through. On the various other hand, if the criteria are also reduced, insufficient combination, absence of infiltration, or undercutting might take place.

Top Quality Guarantee in Welding Procedures

Conclusion

In verdict, grasping the art of welding requires a comprehensive click now understanding of undercut welding, its causes, and strategies to avoid it. By ensuring correct welding specifications and executing quality guarantee methods, flawless construction results can be attained. It is vital for welders to continually pursue excellence in their welding procedures to prevent undercut problems and create high-quality welds.

Undercut welding, an usual problem in welding procedures, takes place when the weld metal does not correctly fill the groove and leaves a groove or anxiety along the welded joint.To prevent undercut welding, welders ought to guarantee proper welding criteria, such as readjusting the current, voltage, traveling rate, and maintaining the proper electrode angle. Inadequate welding incorrect or present welding try here rate can right here also add to damage.To alleviate the risk of damaging in welding, welders can use tactical welding methods intended at enhancing the quality and honesty of the weld joints.In conclusion, grasping the art of welding needs an extensive understanding of undercut welding, its causes, and strategies to prevent it.

Report this page